Carbide snow plow blades are a widely used type of snow plow blade. They are a natural progression from standard steel snow plow edges which were discussed in the first post of this series: Snow Plow Cutting Edges – An Introduction to Steel.

DMC Wear Parts has experts in all aspects of ground engagement edges, blades, and tools. We are doing this educational introduction series to share some of our knowledge with operators so that they can be more efficient and reduce their overhead costs.

To begin, it is important to give a brief overview of this particular snow plow cutting edge style. Carbide snow plow edges are used on the front, underbody, and wing of a snow plow. Carbide snow plow blades look very similar to traditional steel edges; however, they have a carbide insert brazed into the thickness of the steel face along the bottom of the blade. This carbide insert has much better wear resistance properties than a cutting edge made of just steel. This gives the operator the following benefits:

- Longer Wear Life – on average carbide cutting edges have 3-5x more wear lifespan than heat-treated steel edges, and up to 20x more when compared to Carbon Steel

- Even Wear – carbide snow plow cutting edges will wear evenly across the face of the blade, which can help reduce the “crowning” effect that many operators experience with steel edges.

- Saves Time – Because the blades last longer and wear more evenly, operators can spend less time changing blades and more time out on the roads pushing snow.

Types of Carbide Snow Plow Edges

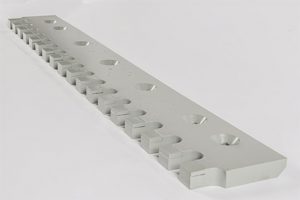

There are a wide variety of carbide edge styles for snow plows. The standard is a flat, 3/4″ thick by 6″ tall blade with a single carbide insert. These edges are great for front mounts, underbodies and wing plows. It is important to note that specific mounting applications have specific additional edge qualities. Specifically, an underbody blade should have a top bevel, whereas front mount and wing blades are unbeveled square edges.

Another type of Carbide snow plow edge is a serrated edge. These blade types are designed for a more aggressive cut that can easily break through hard compacted snow and ice. The blades are easy to identify (as you can see in the picture below) because they have a carbide square welded to the front that look like teeth.

Hybrid Edges

Finally, there are some carbide snow plow edges that are more of a hybrid. These blades can consist of steel and/or rubber in addition to the carbide segments. In these cases, the carbide and steel segments are completely encased in a rubber shell. The most common model for these hybrid blades consist of a steel mounting blade, rubberized carbide segment (pictured below), and a steel cover plate. The mounting plate and cover plate offer stability for the rubber segment.

This setup is beneficial for operators because it helps give a better clean sweep on snow. You can almost think of it as a squeegee effect on the road surface. Plus, the rubber embedded metal snow plow blades offer greater flexibility to contour to changing road surfaces and the rubber also drastically decreases vibration on the machine for a better operating environment.

Carbide snow plow edges are a great way to increase wear life and decrease the time and effort that changing blades creates. The extended wear life of carbide does come at a higher price than a steel edge; but when ran properly the longer wear life and cost savings will be a financial advantage in the long run.

Ideal uses of carbide snow plow cutting edges:

- Highway & interstate roads

- Municipal/city streets

- Private/commercial parking lots

- Residential roads

Please feel free to reach out to DMC Wear Parts to discuss more about carbide snow plow edges and get a quote. There are many different styles to choose from, and as always, we want to provide Parts for Progress. Call (605) 840-8082 or send us a contact form to get more information.