Steel grader blades can help operators meet the needs of any road grading or earthmoving application. Steel blades are inexpensive options that are designed to provide excellent wear life and efficient performance. DMC Wear Parts offers a wide variety of high-quality heat-treated steel grader blades. We offer both flat and curved steel graders blades with or without serrated teeth in a range of dimensions. The descriptions and chart below list some of the more popular profiles.

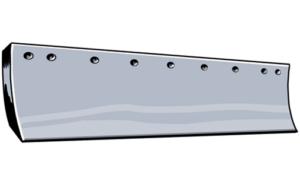

Standard Heat-Treated Curved Grader Blades

Standard Heat-Treated Curved Grader Blades

- Preferred steel blade for general construction, finish grading & road maintenance

- Curved design promotes optimal material penetration & flow

- High resistance to breakage

- Significantly longer wear life compared to Curved Carbon Blades (below)

- Universal 3”- 3”- 6” bolt pattern

- 44-52 HRC

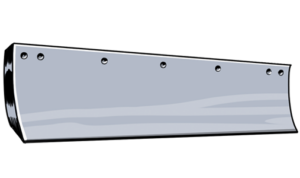

Standard Carbon Curved Grader Blades

Standard Carbon Curved Grader Blades

- Cost-effective option for high abrasion/low impact applications

- Typically used for general construction, finish grading & road maintenance

- Curved design promotes optimal material penetration & flow

- Shorter wear life compared to Curved Heat-Treated Blades (above)

- Universal 3”- 3”- 12” bolt pattern

- 28-32 HRC

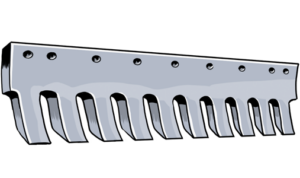

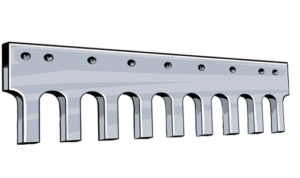

Serrated Heat-Treated Curved Grader Blades

Serrated Heat-Treated Curved Grader Blades

- Superior penetration of packed or frozen material

- Curved design promotes optimal material penetration & flow

- Universal 3”- 3”- 6” bolt pattern

- 44-52 HRC

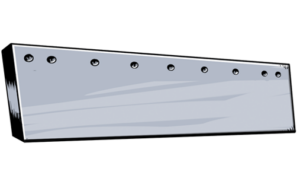

Standard Heat-Treated Flat Grader Blades

Standard Heat-Treated Flat Grader Blades

- Recommended for heavy-duty road maintenance and development

- More wear life compared to Curved Grader Blades

- Superior breakage resistance

- Universal 3”- 3”- 6” bolt pattern

- 44-52 HRC

Serrated Heat-Treated Flat Grader Blades

Serrated Heat-Treated Flat Grader Blades

- Recommended for heavy-duty road maintenance and development of packed or frozen material

- More wear life compared to Curved Grader Blades

- Superior breakage resistance

- Universal 3”- 3”- 6” bolt pattern

- 44-52 HRC

5/8″ HOLES Curved Heat-treated

5/8″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

3/4″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

1″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

5/8″ HOLES Flat Heat-treated

5/8″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

3/4″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

5/8″ HOLES Curved Serrated Heat-treated

3/4″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

3/4″ HOLES Curved Heat-treated

5/8″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

3/4″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

1″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

3/4″ HOLES Flat Heat-treated

5/8″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

3/4″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

3/4″ HOLES Curved Serrated Heat-treated

3/4″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

1″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

3/4″ HOLES Flat Serrated Heat-treated

1″ Thick x 8″ Wide

Thick | Width | Length

Holes

End to 1 | 1st to 2nd | 2nd to 3rd

LBS

Customer Testimonial

“From an operators standpoint conditions are always changing and with the Borox blue steel you have the ability to adapt to different conditions by switching between different cutting-edge styles and thicknesses easily. From a shop foreman standpoint less down pressure to do the job means less wear and tear on the machine, which translates to savings in the long run!”

– Stuart | Road Foreman | North Dakota, USA

Contact Us Today – We Are Here To Help!

With over 20 years of experience, we understand your needs and can help you get the correct road grading equipment for your job. Let us put our knowledge to work for you!

![]() Quick & Free Quotes

Quick & Free Quotes

![]() (605) 840-8082

(605) 840-8082

![]() American Owned

American Owned

Benefits & Uses Of Steel Grader Blades

- These heat-treated blades provide increased wear resistance at a low price point.

- Heat-treated steel blades give greater protection against breakage in higher impact applications.

- Sharp steel cutting edges help to protect the main blade assembly and reduce overall machine wear.

- Grader blades can reduce dust and bring larger gravel particles to the top of the road surface

- Grader blades can reduce the need for continually adding salt and sand to roads in the winter.

- Grader blades can reduce washboards, potholes, and other road slope issues.

Common Applications

DMC Wear Parts’ steel cutting edges are used by operators in a variety of road grading and earthmoving applications in private construction, city/municipal projects, and for other general contracting uses. Some of the most common uses of steel blades include:

- Creating a new road – A flat edge is often best suited for this application as long as the material is not required to be carried along the road surface.

- Heavy-duty road maintenance – A flat blade with a serrated edge is often best suited for this application when better ground penetration is needed.

- Grading hard-packed roads or gravel – A curved blade with serrated teeth will penetrate through the top layer and open heavily impacted grounds while pushing materials over the surface to even the leveling.

- Reconditioning or refinishing a road – A curved edge carries existing material along the top layer to create a smooth and flat finished road surface.

- Breaking through the ice and frozen ground – A curved serrated edge breaks through the ice and frozen earth better than a continuous edge while pushing the material from the road surface.

Other Grader Blade Product Lines

BluSteel Grading System

DMC Wear Parts offers Borox BluSteel grader blades to maximize the performance and efficiency of your motor grader blades.

Carbide Grader Blades

DMC Wear Parts offers a variety of carbide grader blades featuring a carbide insert & carbide overlay that increases the life of the blade.