Ground Engaging Tools (G.E.T.) provide excellent, customizable options to attach to heavy machinery that helps you penetrate and manipulate the earth. From your bulldozer to your snowplow, these powerful tools can make a massive difference when it comes to moving ground! Perhaps your project requires you to dig into the hard ground; adding teeth to your excavator bucket can make the job easier and quicker. Ground engaging tools are a game-changing optimization for your construction equipment. Still, you might be wondering if you need to purchase these parts from an Original Equipment Manufacturer (O.E.M.) or if aftermarket parts are viable.

Continue reading to learn more about DMC Wear Parts’ aftermarket ground engaging tools and how they can often be a much more affordable option while providing the same level of productivity as OEM parts.

What are Ground Engaging Tools?

One of the many uses of heavy machinery is reshaping land for a building project. Breaking ground or clearing debris out of the way can often be the first step in a construction project. Whenever you strike the ground with your machine, with the aid of a tool designed to pierce or impact the ground, you are using ground-engaging tools. Ground engaging tools are a great addition to your equipment.

Adapters for Your Dozer or Bucket

For breaking ground, your G.E.T. adapters are the parts that help get the job done. Used on loaders, excavators, and more, you can add them to your dozer or bucket by welding or bolting them on.

Ground Engaging Tools Help to Match Your Machine to the Job Site

G.E.T. can handle the bulk of the work, protect your machine, and optimize productivity, regardless of the type of job site environment. G.E.T. are a robust category of tools that can be easily swapped, keeping them matched to the work requirements of your job site. There are many kinds of tips, teeth, and blades used to penetrate the ground and dig into the earth. Dozer blades can push enormous piles of dirt, snow, or waste out of the way.

Consider having an expert look at your ground engaging tools to make sure everything is in working order and optimized for each job.

Dozer and Loader Blades

Blades can almost appear like a sizeable scoop-shaped plate. This blade is attached to bulldozers to push large amounts of dirt, snow, or other debris out of the way. Dozer blades can also level the earth, creating a flatter surface for your project. DMC Wear Parts also offers an extensive inventory of motor grader blades, including our BluSteel System, and loader blades.

Bucket Teeth

Excavators, backhoes, loaders, dozers, and graders all utilize bucket teeth. Manufacturers design these machines to remove, dig, and pick up tricky objects. While some types come close, no single kind of bucket teeth is perfect for all job applications. If you’re landscaping, doing demolition work, or using a loader, there is a unique type of tooth for your needs.

Ripper Shanks

Rippers shred and tear apart all kinds of matter. Ideal for farming or reshaping the land, they can drastically loosen the soil and are perfect for hard dirt. Ripper shanks protect the body of your equipment from taking on damage, as breaking up hard ground can be challenging work for any machine.

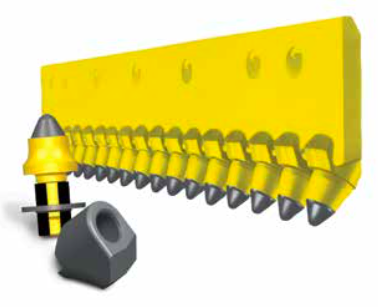

Carbide Scarifier Bits

Scarifier bits (AKA stinger bits) are a useful G.E.T. tool that are mounted onto motor grader scarifier boards. These self-rotating carbide bits are commonly used to penetrate the surface material in road maintenance, gravel maintenance, and road milling.

Aftermarket G.E.T.

Aftermarket G.E.T. can offer a more comprehensive selection of tools at an affordable price. DMC Wear Parts knows this better than anyone, and we offer an extensive inventory of ground engaging tools that are compatible with almost any machine or manufacturer on the market.

Aftermarket Parts vs. OEM Parts

Our part suppliers design and build aftermarket parts to offer the same or better performance as the original part. As a result, the aftermarket part can operate as a replacement of the original part from the manufacturer. Not only that, but you will likely find the aftermarket part you need at a much lower price than their OEM counterpart.

Contact Us – We Are Here To Help

With over two decades of experience, our undercarriage parts experts know the perfect parts for your equipment. Let us put our knowledge to work for you!

![]() Quick & Free Quotes

Quick & Free Quotes

![]() (605) 840-8082

(605) 840-8082

![]() American Owned

American Owned

Benefits of Using Ground Engaging Tools

There are many benefits to G.E.T., namely in the amount of work they allow you to accomplish. If breaking ground, moving debris, or digging deep into the earth is on your to-do list, you will want to make sure your machines have the right tools to handle those assignments. Below are just some ways that ground engaging tools can make a difference in your construction projects and positively impact your productivity.

Extending the Life of Your Equipment

Each day on the job site, walk around your machine and inspect your machine, including its ground engaging tools. Watch out for any signs of wear and tear, like missing parts and bolts. Cleaning the machine and replacing parts on time can also prolong your machine’s life.

Help Reduce Downtime for Your Machine

Keeping up on maintenance can help prevent unnecessary damage and larger issues with your machine. If your equipment has an unexpected part failure in the field, and you must replace it, this could lead to unnecessary downtime or delayed project timelines. Unplanned repairs can lead to extensive downtime for the machine. Downtime might affect your project schedule, which can mean problems with the contract. Avoid this scenario by keeping your machine and any parts of it that impact the ground well-maintained.

Adding Power and Performance

Moving large amounts of earth or shredding through debris can be challenging. Ground engaging tools are durable enough and designed to handle those jobs. G.E.T.’s can help you get the power and performance that you need from your equipment.

Versatility on the Job Site

G.E.T.’s are attached to your machine for a specific purpose. These tools can be switched out, changed, or upgraded as the situation or job requirements change or increase in difficulty. This versatility increases due to the lengthy list of options that are out there for ground engaging tools.

Maintenance for Your Ground Engaging Tools

The best way to proactively care for your equipment is through preventative maintenance. Performing routine maintenance with a prevention mindset allows you to schedule when repairs and replacements might occur. It will enable you to follow a plan and keep your equipment running efficiently.

One of the critical components of preventative maintenance is a regular inspection to monitor the condition of the equipment and its undercarriage parts. When signs appear that a part might need replacing, taking the initiative at the start of the process can prevent costlier problems later down the road.

Choosing the Right Ground Engaging Tools for Your Machine

Choosing the best tool for your machine can affect everything from the machine’s performance, fuel usage, and the amount of money spent on maintenance. Contact one DMC Wear Parts’ aftermarket parts experts today to help find the part that’s right for your machine and your project!

*All uses of manufacturers’ names, symbols, brands, and descriptions are used for reference purposes only and are not implied that any part offered is the product of these manufacturers.