DMC Wear Parts is proud to offer a wide selection of bogie parts & bogie assemblies for tracked equipment. DMC Wear Parts is a leading undercarriage parts supplier with over 50,000 individual parts in stock throughout 12 warehouses in the United States. Our bogie systems are sourced from the top aftermarket parts manufacturers and are designed for efficient, durable, and long-lasting performance.

We offer bogie assemblies that provide exceptional surface traction regardless of the ground conditions, including uneven and rough terrain. Bogie assemblies are an important part of the undercarriage design for many types of track-type equipment. The bogie assemblies are designed to absorb impact loads and reduce the shock that would occur when track-type equipment travels over uneven terrain. As a result of an effective bogie system, the traction is increased, undercarriage durability and wear life can be extended and the operator is more comfortable.

3-Year / 4,000-hour Manufacturer Warranty Coverage For Undercarriage Parts & Bogie Assemblies

Aftermarket Bogie Assemblies

DMC Wear Parts offers aftermarket bogie assembly parts for many leading manufacturers, including Caterpillar, Komatsu, John Deere, Hitachi, and more. Our extensive range of undercarriage parts offers complete solutions for dozers, backhoes, scrapers, crawlers, compact track loaders, excavators, motor graders, pavers, and other track-type equipment. DMC stocks only high-quality undercarriage parts from aftermarket manufacturers with excellent reputations in the construction, road building, road maintenance, forestry, and agricultural industries. One of our suppliers, ITR America, provides the widest range of undercarriage applications with parts for more makes and models than any other supplier.

DMC Wear Parts offers aftermarket parts that are manufactured to the highest quality standards for long wear life and trouble-free performance even in tough conditions. Here are some common bogie replacement part types, please confirm the machine and part number with our parts experts to ensure proper fit.

✓ Major Bogies

✓ Minor Bogies

✓ Cartridge Pins

✓ Track Guides

✓ Roller Caps

✓ Idler Caps

✓ Rubber Pads

✓ Covers

✓ Inserts

✓ Retainers

Contact Us For Ordering & Pricing Information

With over 20 years of experience, we understand your equipment needs and can help you get the correct undercarriage bogie assembly for any model and manufacturer. Let us put our knowledge to work for you!

![]() Quick & Free Quotes

Quick & Free Quotes

![]() (605) 840-8082

(605) 840-8082

![]() American Owned

American Owned

Bogies For Major Manufacturers

DMC Wear Parts carries aftermarket bogie parts and complete bogie assemblies for makes and models of all major manufacturers. DMC Wear Parts carries complete bogie assemblies that are operable and interchangeable with OEM components. There are many key components to a bogie assembly, including major and minor bogies, cartridge pins, track guides, rubber pads, roller and idler caps, idler caps, inserts, covers, and retainers. Below are some of the highlights of our aftermarket parts Caterpillar (CAT) and Komatsu track-type equipment.

Caterpillar Bogie Assemblies

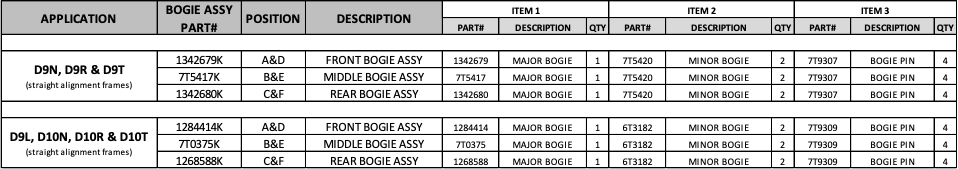

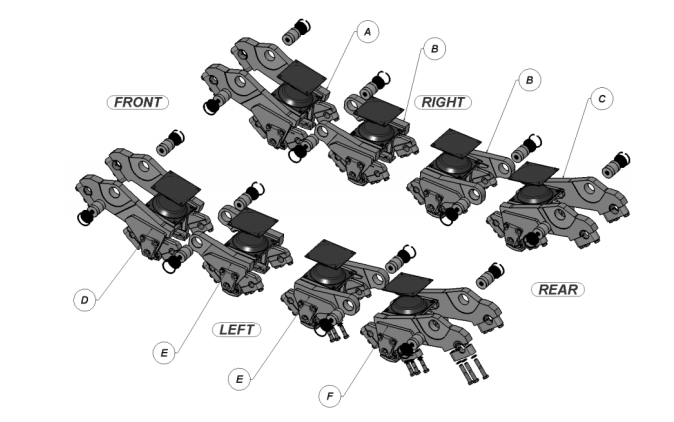

Download our brochure featuring complete bogie assemblies for popular caterpillar machines. Below is a chart of complete bogie assy’s for the popular Caterpillar applications and an associated diagram.

(Click on the image or download the complete brochure for a larger version of the chart)

Komatsu Bogie Assemblies

Check out this video from one of our parts suppliers, ITR (USCO.IT) that features the assembly of an ITR BOGIE Kit for Komatsu D155. We also carry aftermarket parts for the Komatsu X-Type Bogie and REU system (resilient equalized undercarriage).

What is a bogie assembly?

Bogie assemblies are an essential part of the undercarriage for many track-type heavy machines. There are a variety of bogie assembly designs, depending on the equipment make, model, and manufacturer. In general, the bogie assembly supports crawler-type movement across uneven terrain. Below are some of the potential benefits of undercarriage bogie assemblies

- Better ride smoothness in rough terrain

- Increased traction on uneven ground

- Support heavy equipment suspension

- Easier passing ditches, holes, and gaps

- Less ground impact and surface damage

- Improved surface load placement

In addition to complete bogie assemblies, we also offer undercarriage parts, steel and rubber tracks, and heavy-duty parts that are engineered for intense conditions and extreme applications. With a full catalog of undercarriage parts, you can count on DMC Wear Parts to have what you need to keep your equipment moving.

How does a bogie assembly work?

Tracked undercarriages and crawler-type movement are advantageous for providing a greater surface area but can be limited by uneven terrain. In some equipment types, a bogie assembly or bogie wheel structure is connected to the frame and positioned between the front and rear idlers to allow the frame to adjust to uneven terrain. Some tracked equipment models are designed with bogies as external suspension components to reduce traction and smooth the ride across uneven ground.

Protecting and maintaining bogie assemblies

It is important for operators to be proactive about proper maintenance. Repairing even the smallest parts is crucial to prevent unnecessary wear on other parts that could lead to more costly and time-consuming repairs.

Operators should inspect their equipment at the start of the workday. Begin with a walk around the machine examining the undercarriage for imperfections or material buildup. Operators should try to identify any broken or damaged bearings, sprockets, bolts, springs, or other components. If you notice that the bogies are showing excessive wear or crumbling, replace them immediately as the machine will not operate as smoothly.

During operation, the undercarriage may get material built up and should be cleared from the tracks, rollers and idlers, bogie assembly, and other components. Proper maintenance and intelligent operation can protect your parts and bottom line.