DMC Wear Parts is proud to be an official KENNAMETAL parts dealer. Our scarifier blades and accessories are effective road grading solutions that outlast traditional steel blades. Scarifier blades maintain an even cutting height by allowing the individual carbide-tipped bits to rotate for uniform wear and longer tool life. The ability to swap individual bits means that they can be quickly moved from position to position, without removing entire blade sections, to prevent crowning that can occur with traditional grader blades.

![]() Quick & Free Quotes

Quick & Free Quotes

![]() (605) 840-8082

(605) 840-8082

![]() American Owned

American Owned

Scarifier Blades & Boards

Kennametal’ scarifier blades are easier to use and more versatile than competitive systems. The surface engagement angle of the cutting tools is preset for optimum tool rotation, ease of use, and performance. Kennametal scarifier blades are available in three different styles that are designed to perform optimally in a range of ground conditions:

Standard-Duty Blades — Ideal for light-use road grading in average conditions and applications.

Heavy-Duty Blades — Generally ideal for road grading in most conditions and applications.

Severe-Duty Blades — Ideal for grading in extreme road conditions and applications. These scarifier blades feature a 6″ (152mm) blade width instead of the 5″ (127mm) width of standard-duty and heavy-duty blades. This provides more clearance between the toolholder blocks on the back of the blade and the “frog” of the moldboard. The severe-duty also include extra-heavy welds to reduce block breakout from the blade.

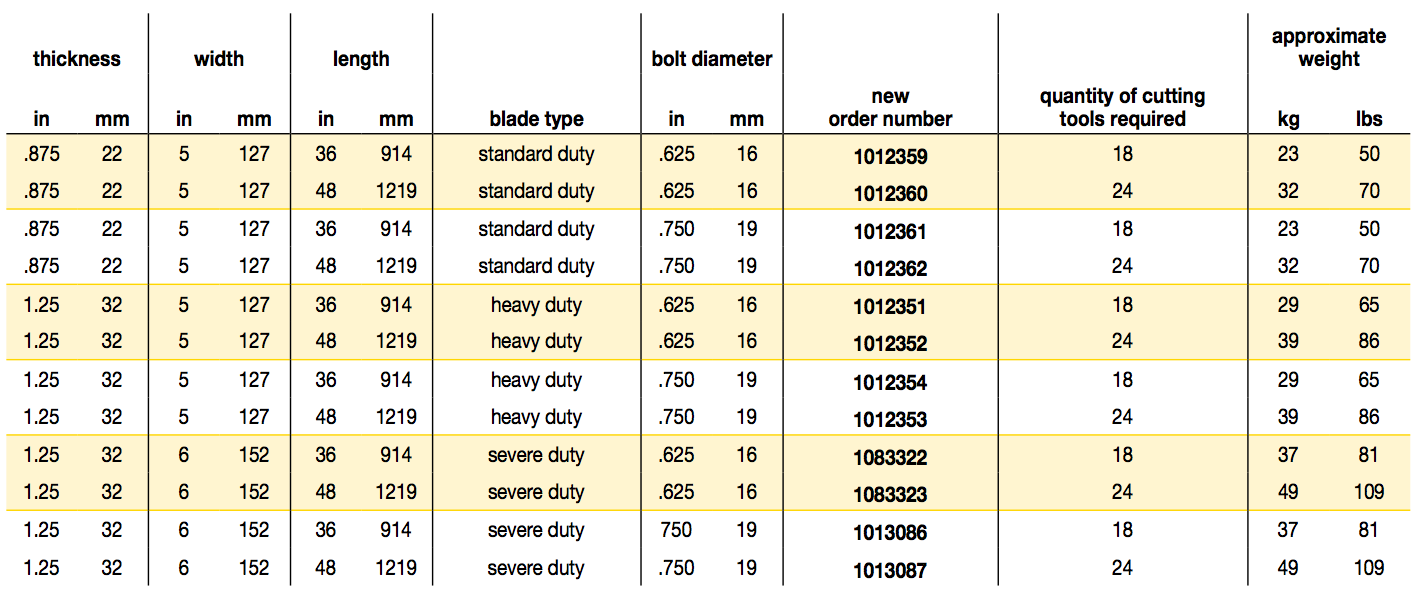

Scarifier Blade Chart & Ordering Information

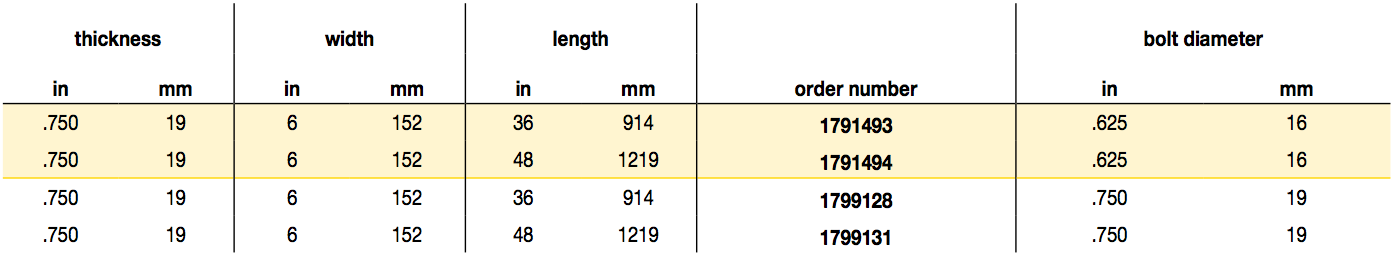

NOTE: Kennametal recommends the use of Grade 8, Number 3 head-plow bolts and nuts when installing blades.

Contact A DMC Wear Parts Sales Expert Today!

Blade Selection Guide for Various Moldboards Lengths

- If you have a 12-foot moldboard [144″ (3658mm)], you will need (3) sections of 48in length (1219mm) and 72 carbide-tipped scarifier bits.

- If you have a 13-foot moldboard [156″ (3962mm)], you will need (3) sections of 36in length (914mm) and (1) section of 48in length (1219mm) and 78 carbide-tipped scarifier bits.

- If you have a 14-foot moldboard [168″ (4267mm)], you will need (2) sections of 36in length (914mm) and (2) sections of 48in length (1219mm) and 84 carbide-tipped scarifier bits.

- If you have a 16-foot moldboard [192″ (4877mm)], you will need (4) sections of 48in length (1219mm) and 96 carbide-tipped scarifier bits.

3′ Heavy Duty Scarifier Board

- Description: 1.5″ Tool Spacing, Fits all 22mm rotating bit styles

- Application: Gravel Maintenance

- Dimensions 1 1/4″ x 6″ x 36″

4′ Heavy Duty Scarifier Board

- Description: 1.5″ Tool Spacing, Fits all 22mm rotating bit styles

- Application: Gravel Maintenance

- Dimensions 1 1/4″ x 6″ x 48″

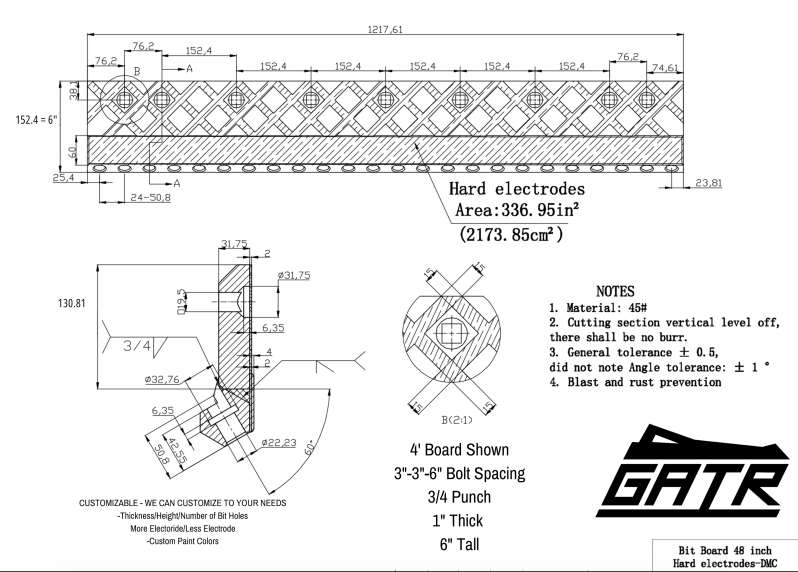

4′ GATR EXTREME Board

- Description: 6 bits per foot – fits all 22mm rotating bit styles

- Application: Multiple Applications

- Dimensions 1″ x 6″ x 48″ (Customizable To Fit Your Needs)

GATR EXTREME Scarifier Boards

GATR EXTREME scarifier boards are engineered to protect the boards from washing, protect bolt heads, and eliminate the need for cover plates. These boards are designed with 6 holes per foot and can be used with any 22mm rotating bits. The standard dimensions are 1″ x 6″ x 48″, but they can be customized for specific needs.

Download GATR EXTREME Scarifier Boards Brochure

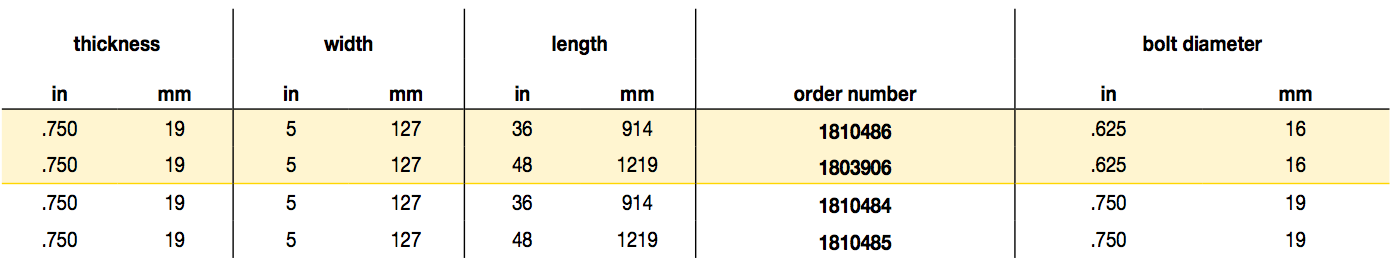

Scarifier Cover Blades

Optional cover blades provide exceptional wear resistance and superior protection of the main blade body when the scarifier system is operating in extremely abrasive conditions or when carrying heavy debris loads on the moldboard.

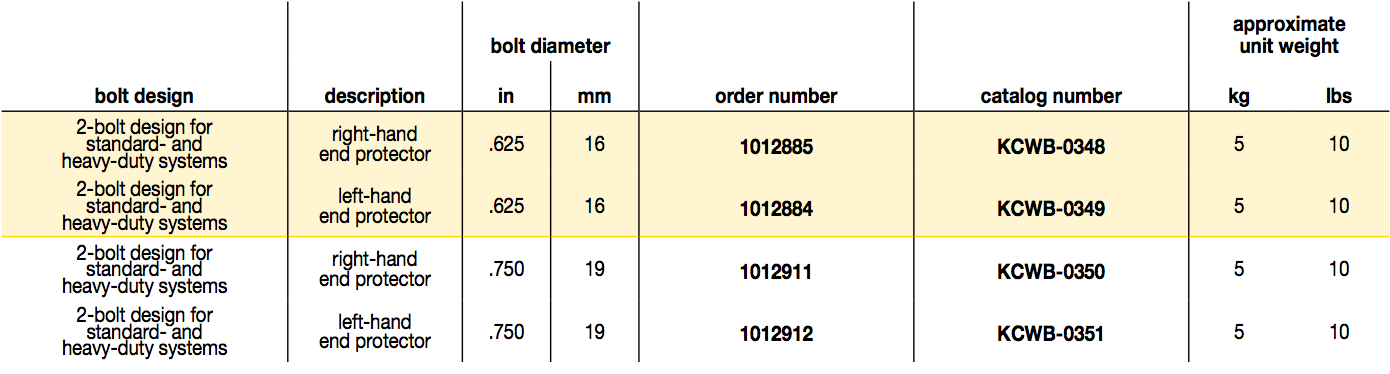

Cover blades attach easily through existing bolt holes on the blade using bolts that are .750″ (19mm) longer than the traditional bolt used to attach the blade to the moldboard.

Standard-Duty Cover Blades

Severe-Duty Cover Blades

Scarifier End Protectors

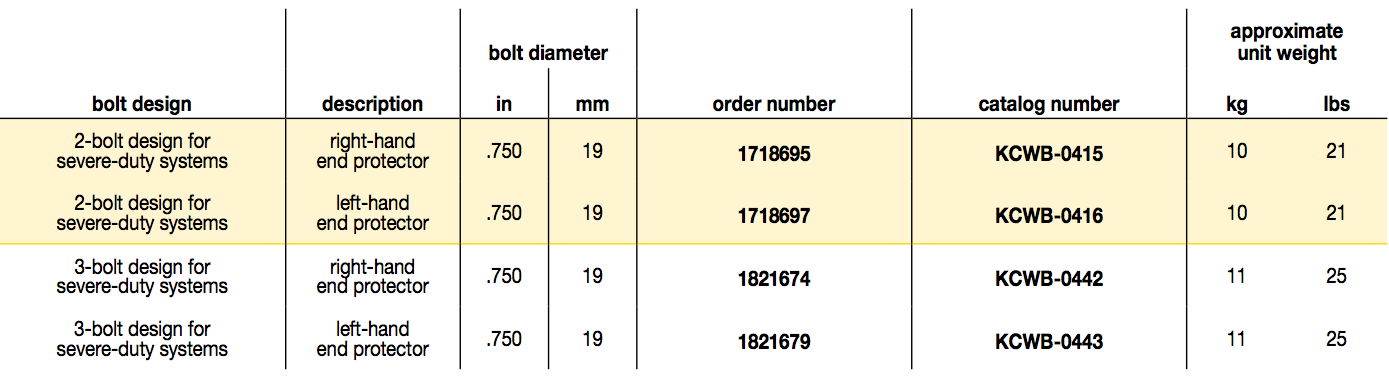

Scarifier Blade end protectors feature a heavy-duty design and tough steel that is designed to resist breakage and bending in any road application. Our end protectors feature Kennnametals’ KenCastTM composite material that combines the wear resistance of exclusive tungsten carbide with the ductility of air-hardening steel.

Standard-Duty and Heavy-Duty End Protectors

Severe-Duty End Protectors

Scarifier Accessories

DMC Wear Parts offers a variety of scarifier blade accessories to improve the performance of your scarifier blade system.

KHP2 Hammer Punch

- For removing cutting tools from blocks.

- Hardened tip for longer life; used with a hammer.

- Plastic hand protector for added safety.

KAHP1 Air-Hammer Punch

- For removing cutting tools from blocks.

- Hardened tip for durability.

- Fits all light-duty, air-hammer guns that have a .375″ (10mm) chuck.

KAHP 1D Air-Hammer Punch

- For removing cutting tools from blocks.

- Hardened tip for durability.

- Fits all heavy-duty, air-hammer guns that have a .500″ (13mm) chuck.

C87GB Block

Easily welded with a 7018 or 8018 low-hydrogen rod with no pre-heating required.

LR87

Replacement retainer for use with C387DS, AR15087, C387BF, KCWB-0448, and C87BF cutting tools.

LR85

Replacement retainer for use with C855DS, C855HD, C855HDX, C855LR, C855KCSB, and C855HDX-4 cutting tools.

Reducer Brushing

Reduces bolt hole size in blades from .750″ (19mm) bolt to .625″ (16mm) bolt.

Looking For Carbide Bits & Scarifier Cutting Tools?

Customer Testimonial

“From an operators standpoint conditions are always changing and with the Borox blue steel you have the ability to adapt to different conditions by switching between different cutting-edge styles and thicknesses easily. From a shop foreman standpoint less down pressure to do the job means less wear and tear on the machine, which translates to savings in the long run!”

– Stuart | Road Foreman | North Dakota, USA