The BluSteel grader blade system will solve all of your road grading needs! This system is designed to maximize the performance of your motor grader while saving you money and time. Road authorities in over 100 counties have improved their efficiency with BluSteel’s increased blade lifespan, reduced fuel expenses, and saved time changing blades. Check out the products below for more information or jump to the bottom for FAQs about the Borox BluSteel Road Grading System.

DMC Wear Parts is a proud distributor of Borox Wear Parts.

BluSteel Grader System

There are 6 different blades profiles that can be quickly changed out to match your working conditions. This allows you to quickly transform your grading equipment into any style of cutting edge in one system. To swap styles with the quick-change all you need is one person and a hammer.

- Need to fill potholes and fix washboards? – Use a BluSteel corrugated cutting edge.

- Need to cut? – Use a BluSteel serrated blade.

- Need to maintain gravel? – Use a BluSteel flat blade.

- Need to scarifier? – Use a BluSteel scarifier blade attachment.

- Need to push snow? – Use a BluSteel flat blade.

- Need to cut ice? – Use a BluSteel corrugated cutting edge.

- Need to …? – Use BluSteel!

All of your road maintenance needs can be solved with one system that saves you time and money!

Click Play To See BluSteel Grader Blades In Action

BX500 3’

- Part: #1258091

- Dimensions: 9.87″ x 3/8″ x 36″

- Description: The BX500 is designed to eliminate harmful road conditions such as potholes, washboards, ice, snow, dirt, and mag-chloride infused roads. The corrugation allows for a greater mix of material than standard grader blades.

BX500 4’

- Part: #1258122

- Dimensions: 9.87″ x 3/8″ x 48″

- Description: The BX500 is designed to eliminate harmful road conditions such as ice, washboarding, potholes. The corrugation allows for a greater mix of material than standard grader blades.

BX 500 3’ Extra Tall

- Part: #1259091

- Height: 300 MM Tall

- Description: The BX500XT is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is 60 mm taller than the BX500 blade. The corrugation allows for greater mix of material than standard grader blades.

BX 500 4’ Extra tall

- Part: #1259122

- Height: 300 MM Tall

- Description: The BX500XT is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is 60 mm taller than the BX500 blade. The corrugation allows for a greater mix of material than standard grader blades.

BX550 HD 3’

- Part: #1258004

- Height: 240 MM Tall

- Description: The BX550 HD is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is thicker than the BX500 for more wear and more severe conditions. The corrugation allows for a greater mix of material than standard grader blades.

BX 550 HD 4’

- Part: #1258005

- Height: 240 MM Tall

- Description: The BX550 HD is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is thicker than the BX500 for more wear and more severe conditions. The corrugation allows for a greater mix of material than standard grader blades.

Flat 3’

- Part: #1025091

- Dimensions: 9.87″ x 3/8″ x 48″

- Description: The Flat is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is a solid blade, making it less aggressive than the corrugated blades and serves as a maintaining blade or snow pushing blade. Run one flat on the edge of your blade for shoulder work.

Flat 4’

- Part: #1025122

- Description: The Flat is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is a solid blade, making it less aggressive than the corrugated blades and serves as a maintaining blade or snow pushing blade. Run one flat on the edge of your blade for shoulder work.

Flat Long Life 5/8” 3′

- Part: #1014005

- Height: 240 MM Tall

- Description: The Flat Long Life 5/8” is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is a solid blade, making it less aggressive than the corrugated blades and serves as a maintaining blade or snow pushing blade. The extra thickness adds more wear life over standard grader blades.

Flat Long Life 5/8″ 4’

- Part: #1014003

- Height: 240 MM Tall

- Description: The Flat Long Life 5/8” is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is a solid blade, making it less aggressive than the corrugated blades and serves as a maintaining blade or snow pushing blade. The extra thickness adds more wear life over standard grader blades.

Flat LL 3/4” 3’

- Part: #1015001

- Height: 240 MM Tall

- Description: The Flat Long Life 3/4” is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is a solid blade, making it less aggressive than the corrugated blades and serves as a maintaining blade or snow pushing blade. The extra thickness adds more wear life over standard grader blades.

Flat Long Life 3/4” 4’

- Part: #1015002

- Height: 240 MM Tall

- Description: The Flat Long Life 3/4” is designed to eliminate harmful road conditions such as ice, washboarding, potholes. It is a solid blade, making it less aggressive than the corrugated blades and serves as a maintaining blade or snow pushing blade. The extra thickness adds more wear life over standard grader blades.

BX550HD XL 3’

- Part: #1258501

- Height: 240 MM Tall

- Description: The BX550HD XL is designed for extreme wear and extreme conditions. Its 3/4” thick profile along with its corrugated teeth provide the maximum cutting power and wear into one grader blade.

BX550HD XL 4’

- Part: #1258500

- Height: 240 MM Tall

- Description: The BX550HD XL is designed for extreme wear and extreme conditions. Its 3/4” thick profile along with its corrugated teeth provide the maximum cutting power and wear into one grader blade.

2′ Quick Change Carbide

- Description: The quick-change carbide enables operators to easily switch between steel blades and carbide blades. The quick-change carbide is a cemented carbide embedded into the blade, not an insert that can break out. This blade will greatly increase wear when operating on hard, dry roads or when pushing snow.

3′ Quick Change Scarifier

- Part: #1258122

- Preferred Bit Style: DM-C855HD With Circle Washer

- Description: The quick-change scarifier enables operators to easily switch to a scarifier bit system. The board takes a 22mm rotating carbide bit, allowing for maximum cutting ability in extreme conditions. The blade mounts with the wedge just like other blade options. Take a look at our carbide bits for different bit options.

4′ Quick Change Scarifier

- Preferred Bit Style: DM-C855HD With Circle Washer

- Description: The quick-change scarifier enables operators to easily switch to a scarifier bit system. The board takes a 22mm rotating carbide bit, allowing for maximum cutting ability in extreme conditions. The blade mounts with the wedge just like other blade options. Take a look at our carbide bits for different bit options.

Wedge Bolt

- Part: #1810001

- Dimensions: 9.87″ x 3/8″ x 48″

- Description: Bolt that accepts wedge.

Wedge

- Part: #1820004

- Dimensions: 9.87″ x 3/8″ x 48″

- Description: Wedge to hold blade, slides into wedge bolt.

Support Washer

- Part: #1850070

- Dimensions: 9.87″ x 3/8″ x 48″

- Description: Holds wedge bolt.

Fuel Savings & Universal Fit

The BluSteel system offers optimal efficiency and savings. BluSteel blades are a universal fit for all graders and conditions. The cutting edges are operated at an angle with hardened blades to reduce the RPMs. This means huge fuel savings, reduced tire and hydraulics wear, and less operator fatigue. Some of our customers have cut fuel costs by 40%.

Blade Hardness & Long Life

![]()

BluSteel blades are extremely durable with an extended wear life. The cutting edges are made of up to 600 brinell hardened steel, which is much higher than standard steel (420 brinell). This higher quality steel will increase the typical wear life of your blade and will also make it much easier to operate them at maximum cutting efficiency.

Quick Change & Time Savings

![]()

Every type of blade has its job and the beauty with the BluSteel grading system is that you can quickly change between them when you need a different application. The BluSteel cutting edges are easily mounted and adjusted on the roadside with only minimal hand tools required. Plus, easy changes means less down time.

Customer Testimonial

“From an operators standpoint conditions are always changing and with the Borox blue steel you have the ability to adapt to different conditions by switching between different cutting-edge styles and thicknesses easily. From a shop foreman standpoint less down pressure to do the job means less wear and tear on the machine, which translates to savings in the long run!”

– Stuart | Road Foreman | North Dakota, USA

With over 20 years of experience, we understand your needs and can help you get the right grading equipment for your job. Let us put our knowledge to work for you!

![]() Quick & Free Quotes

Quick & Free Quotes

![]() (605) 840-8082

(605) 840-8082

![]() American Owned

American Owned

How does the BluSteel system work in different road conditions?

We offer many different styles of blades to combat whatever type of road/work situation you encounter. Naturally, the BluSteel system works great with gravel roads, sandy soil, and other easily maintained roads. But what about other conditions?

- Washboards & Potholes – The BluSteel system works to fix washboard roads and potholes instead of just filling them in. The strong BluSteel blades cut to remove imperfections while leaving a surface with improved grooves and traction. This also allows salt and sand to remain in place for longer effectiveness.

- Vegetation & Plant Growth – The BX500 does a great job of breaking up vegetation as it is processed through the holes of the blades. The BX500 style cutting edge also mixes plant growth into the road-base. Plus, the rotation and flow of materials on the blades allows loose vegetation to blow off instead of leaving huge clops of materials.

- Rough & Hard Roads – Rough and hard roads are tough on every grading blade. The thing to consider here is that BluSteel blades offer the ability to improve the road by being able to cut and rotate the material you do have. There is no blade that will be an overnight “infomercial wow” effect, but over time the road will continue to get better and bring up more material. It is also worth noting, as your road gradually improves your edges will start lasting longer as well.

- Ditching – When working with ditching it is time to switch to the thinnest BluSteel flat blade. This blade is perfect for ditching. The short blade widths and the thin flat blade will help you to avoid snapping or bending while managing ditches.

Note: You also have to option to use two different styles of blade at the same time. That means you can use a different blade on a ditch or vegetation side.

Experience The BluSteel Grading System!

Step 1: Schedule a demo time/date at your location.

Step 2: DMC Representative brings BluSteel blades, helps install, and answers questions on site.

Step 3: Test the BluSteel system on your roads with your rep while fine-tuning the blade running angle.

Step 4: Experience the benefits of the BluSteel grading system as you cut/shape your road surface

Step 5: After 2 weeks you get to decide if the BluSteel system is right for you.

Road Grading Questions & Discussion

Below are some of the most popular questions about the BluSteel Grader System.

How does BluSteel save fuel?

Fuel economy is dependent on RPM. The more work a machine has to do the higher the RPM’s necessary to do that work. Using BluSteel cutting edges allows you to cut or maintain your roads at lower RPM’s. This results in lower fuel consumption. Some of our customers have even cut fuel costs by 40%!

Fuel savings and lower RPMs come from two aspects of the system. First, always having a sharp edge makes the cutting easier. BX500 blades, when run correctly negative (15-20 degree angle), will always maintain a sharp edge. This will make it easier to cut requiring less work and fewer RPM’s which saves fuel. Second, the thickness of the BluSteel blades is easier to work with and slices through the ground with fewer RPMs. The BX500 is 1/2″ thick, which is ¼” thinner than the standard blade. The combination of a sharp, thin blade leads to less machine output required for the same project. This lowers your RPM and saves a lot of fuel.

How do BluSteel blades wear?

The BluSteel Grading system solves the problem of uneven blade wear. The magic of BluSteel is that you can run it back, keeping the edge sharp. Plus, the ability to rotate blades helps maintain a straight edge so the operator can cut equally and maintain a slope.

The BluSteel Grading system solves the problem of uneven blade wear. The magic of BluSteel is that you can run it back, keeping the edge sharp. Plus, the ability to rotate blades helps maintain a straight edge so the operator can cut equally and maintain a slope.

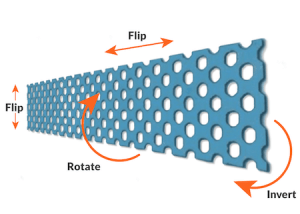

Instead of having a 7′ or 8′ blade that is uneven you have a 3′ or 4′ blade. These shorter blades can be rotated inside out, flipped over, or inverted to “play” your wear. That means instead of torching away your dollars you can quickly rotate the blade to evenly wear and keep a straight edge. Finally, the hardness of the blade is the cherry on top that provides longer use before the steel wear warrants replacement compared to conventional edges.

How do you mount, install, & change BluSteel blades?

The system is meant to give you unmatched versatility and keep the grader out on the road working rather than sitting in the shop getting the blade switched. No air tools are required, limited downtime, and there is no more deadheading back to shop to change a blade. For helpful tips on how to mount and install your BluSteel blades, download this quick guide.

Most of the Borox BluSteel products are based on the Scandinavian system with wedge/wedge bolt and mounting adaptor plate in combination with efficient blades. The blades all fit onto the same mounting board system. The adaptor plate is bolted to the moldboard and the plow blades are secured with a wedge and wedge bolt. Thanks to the adapter plate you can quickly and easily change new plow blades and/or flip over existing blades – all you need is a powerful hammer.

Operators that roll their blades out and over are best suited for the BluSteel system because it basically creates a “table”. Then you can easily hit the wedges out, rotate your blades, set the blades down flat, and re-enter the wedges. Plus, the BluSteel system is designed with 3’ or 4’ width blades so you can carry a different style of blades on the machine with you.