Keeping your motor scrapers in top condition is essential for efficiency, productivity, and cost-effectiveness on the job site. That’s why we offer a comprehensive range of motor scraper parts designed to meet the highest standards of quality and durability.

Aftermarket Motor Scraper Replacement Parts

Our inventory includes a wide variety of parts to suit different models and makes of motor scrapers, ensuring that we have what you need to keep your equipment running smoothly. Our product line includes:

- Cutting Edges and Blades: Built to withstand the toughest conditions, our cutting edges and blades are designed for high wear resistance and longevity. Available in different profiles and thicknesses to match various applications.

- Teeth and Adapters: Our heavy-duty teeth and adapters are engineered for maximum penetration and wear resistance, ensuring efficient material handling and minimal downtime.

- Hydraulic Cylinders and Components: Keep your motor scraper operating with precision and power with our selection of hydraulic cylinders, seals, and other hydraulic components.

- Wear Liners and Protective Parts: Enhance the lifespan of your motor scraper with high-quality wear liners, shoes, and other protective parts that reduce wear and tear on critical components.

- Transmission and Engine Parts: High-performance parts to keep your motor scraper’s powertrain running smoothly, including clutches, gears, and bearings.

Extensive Selection of Parts by Popular Manufacturers

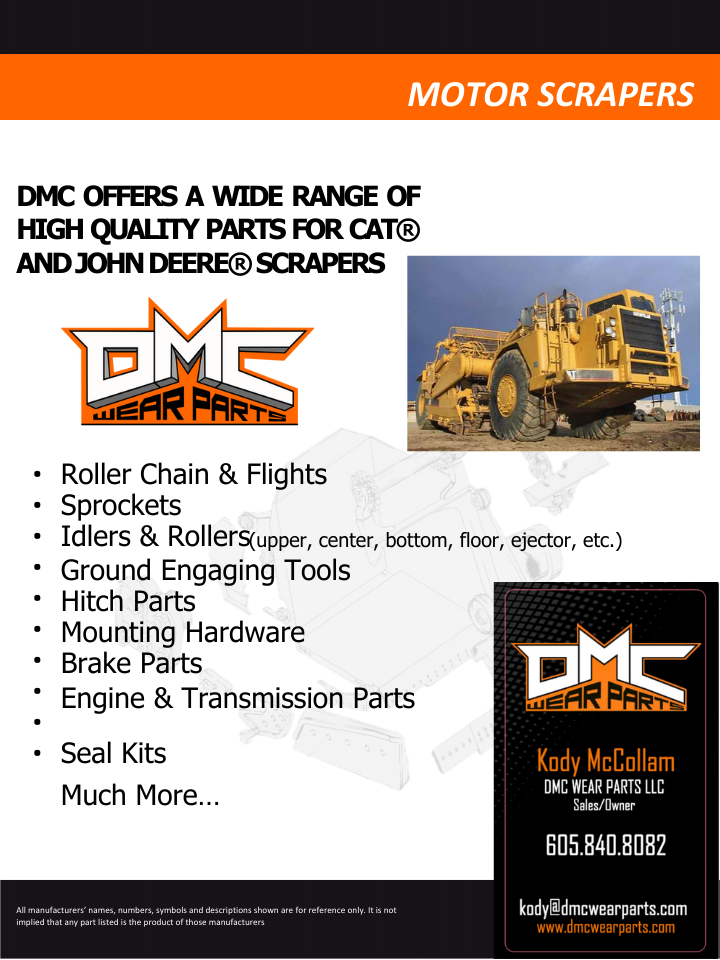

DMC Wear Parts is a leading supplier of aftermarket heavy equipment parts. We stock a broad range of parts for various motor scraper brands, including Caterpillar, John Deere, Terex, and more. Whether you need a replacement part or a specialized component, we have you covered.

![]() Quick & Free Quotes

Quick & Free Quotes

![]() (605) 840-8082

(605) 840-8082

![]() American Owned

American Owned

Why Choose DMC Wear Parts For Your Aftermarket Heavy Equipment Parts?

Your motor scraper’s performance is only as good as the parts it uses. With DMC Wear Parts, you can trust that you’re getting reliable, durable, and high-performing parts that are built to last. Invest in quality and keep your operations running smoothly and efficiently.

- Superior Quality and Durability: Our motor scraper parts are manufactured using top-grade materials and cutting-edge technologies to ensure they meet or exceed OEM standards. This means fewer replacements, less downtime, and more productivity.

- Competitive Pricing: At DMC Wear Parts, we believe in offering high-quality parts at fair prices. Our extensive supply network allows us to provide cost-effective solutions without compromising quality.

- Expert Support and Service: Our knowledgeable team is here to help you find the right parts for your specific needs. With years of experience in the heavy equipment industry, we offer valuable insights and support to help you maintain and optimize your motor scrapers.

- Fast Shipping Nationwide: We understand that downtime can be costly. That’s why we offer fast and reliable shipping across the United States to get you the parts you need when you need them.

Scraper Inspection & Maintenance

Maintaining your motor scraper in peak condition is crucial for ensuring efficient operation, reducing downtime, and extending the lifespan of the equipment. Regular inspection and maintenance are essential to catch wear and tear early, prevent costly repairs, and keep your motor scraper running smoothly in even the most demanding conditions. At DMC Wear Parts, we’re committed to helping you maximize the value of your equipment with high-quality parts and expert advice.

Best Practices for Motor Scraper Maintenance

- Daily Walk-Around Inspections: Conduct a daily walk-around inspection before starting the motor scraper. Look for signs of leaks, worn parts, or potential issues. Address any problems immediately to prevent minor issues from becoming major repairs.

- Follow the Manufacturer’s Maintenance Schedule: Adhere to the manufacturer’s recommended maintenance schedule for routine services like oil changes, filter replacements, and lubrication. Regular maintenance helps ensure optimal performance and prevents premature wear.

- Use High-Quality Replacement Parts: When replacing parts, always choose high-quality, durable components like those offered by DMC Wear Parts. Using inferior parts can lead to increased wear and reduce the lifespan of your motor scraper.

- Monitor Fluid Levels and Condition: Regularly check fluid levels for the engine, transmission, hydraulic system, and coolant. Replace fluids at recommended intervals and monitor for any signs of contamination or deterioration.

- Lubricate Moving Parts: Ensure that all moving parts, including pins, bushings, and articulation joints, are adequately lubricated to reduce wear and prevent seizing. Proper lubrication also helps in reducing noise and improving the machine’s efficiency.

- Keep It Clean: Regularly clean the motor scraper, especially around the engine, radiator, and air filters, to prevent the buildup of dirt, debris, and other contaminants. A clean machine is easier to inspect and maintain.

By following these inspection and maintenance tips, you can ensure that your motor scraper remains reliable and productive for years to come. At DMC Wear Parts, we offer a wide range of high-quality replacement parts to keep your equipment running at its best. From cutting edges and hydraulic components to undercarriage parts and more, we have everything you need to maintain your motor scraper.

Other Types of Heavy Equipment

At DMC Wear Parts, we understand that every job site requires a variety of heavy equipment to get the job done efficiently and safely. Beyond motor scrapers, we provide an extensive range of high-quality parts and components for a wide variety of heavy machinery used in construction, mining, agriculture, and other industries. From ground-engaging tools to undercarriage parts and hydraulic components, our inventory covers all your heavy equipment needs.

- excavators & mini-excavators

- dozers

- backhoes

- motor graders

- skid steers

- wheel loaders

Frequently Asked Questions From Operators

How often should I inspect and replace the cutting edges on my scraper?

The frequency of inspection and replacement of cutting edges depends on several factors, including the type of material being moved, the operating conditions, and the quality of the cutting edges. Generally, operators should:

- Inspect Daily: Perform daily inspections to check for signs of wear, cracks, or damage. If the cutting edge shows significant wear or uneven wear, it should be replaced immediately.

- Replace When Necessary: Replace cutting edges when they are worn down to about 50% of their original thickness or when they start to impact performance. Using high-quality, wear-resistant cutting edges from DMC Wear Parts can help extend intervals between replacements.

What are some signs that my scraper’s transmission or drivetrain needs attention?

The transmission and drivetrain are critical components that need regular inspection and maintenance. Signs that your scraper’s transmission or drivetrain may need attention include grinding noises, fluid leaks, poor shifting, and overheating. If you notice any of these signs, it’s important to inspect the transmission and drivetrain components and perform necessary maintenance or repairs. Using high-quality parts from DMC Wear Parts can help keep your scraper running smoothly and efficiently.

Does DMC offer scraper parts and accessories other than those mentioned on this page?

Yes, DMC Wear Parts offers a wide range of motor scraper parts and accessories beyond those mentioned on this page. We understand that every job and machine is unique, which is why we have a large inventory of 50,000 parts with 12 warehouses located across the country for fast shipping.